Automates and Organises Quality Assurance in Radiation Therapy and Medical Imaging

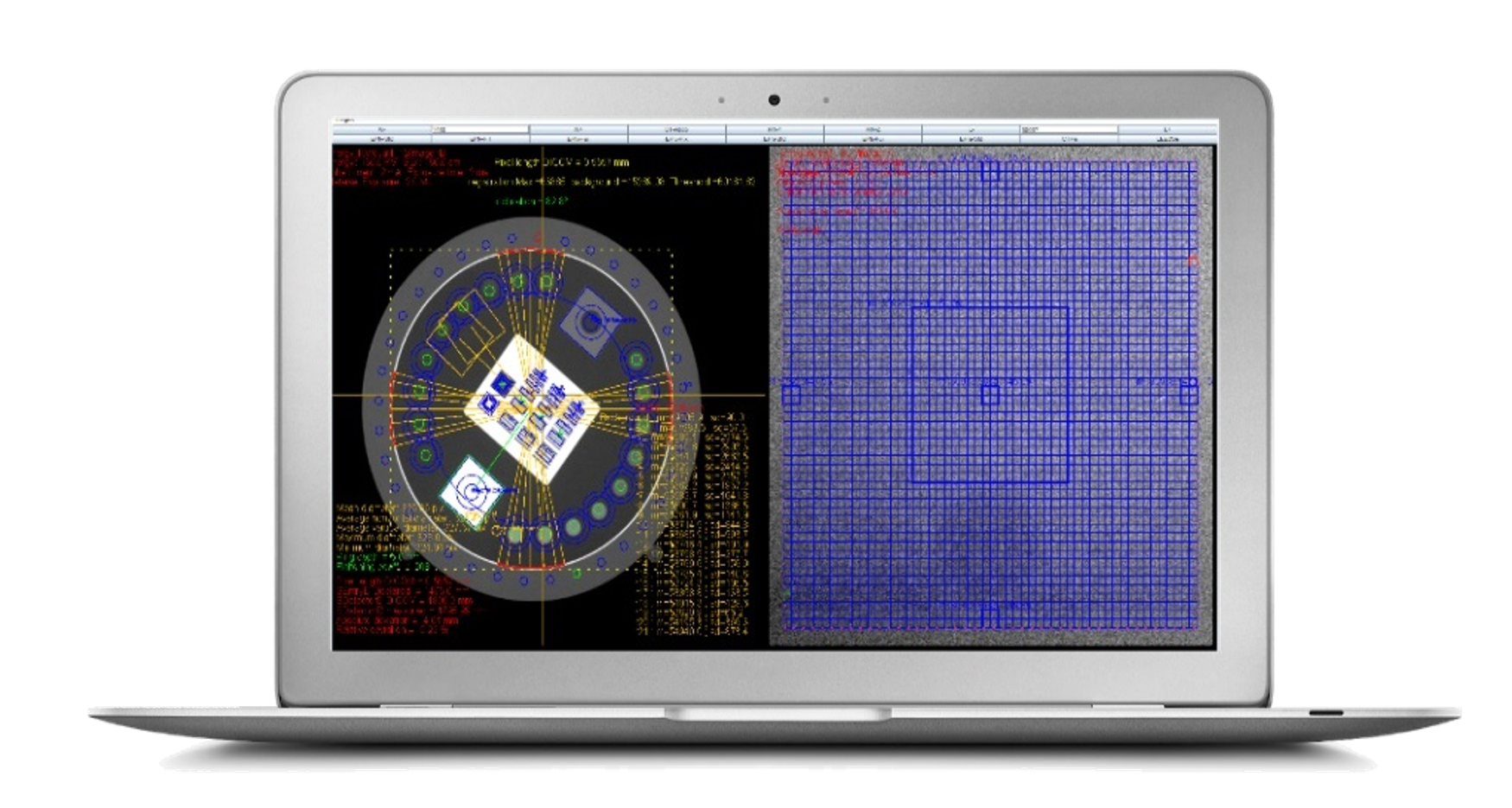

QUALImagiQ-CK

The optimal solution to automate CYBERKNIFE® QA combined with a high-energy portable imager

No More radiographic films !

We offer A VERy POWERFUL, COMPLETE AND INDEPENDENT TOOL FOR ANALYSING AND TRACKING THE quality controls (qc) of your cyberknife installation

Our solution for cyberknife quality control is integrated into the practical, ultra-high performing environment of the qualimagiq software platform:

- QUALIMAGIQ offers a simple and fluid workflow: it takes just 2 mouse clicks to obtain an on-screen analysis report, a third click to edit up to 6 different PDF reports of this analysis, with trend curves for each result.

- While remaining fully configurable: QC protocols, analysis methods and reports can all be customised as you see fit.

- Having very practical tools to review all your QC analysis reports and consult the trend curves associated with each result.

Our QUALIMAGIQ-CK solution allows, without film and without a water tank, ultra-rapid QC of the ballistic precision of the beams, their characteristics, and their collimations but also of the kv imagers integrated into the cyberknife. This solution includes:

- A large and precise high-energy (MV) portable imager

- A set of specific and efficient test objects and accessories

- A software component to acquire MV images of the tested beams

- Software component to convert in DICOM, kV images from ACCURAY

- Software modules to automatically analyse MV and kV images

- The high-energy (MV) portable imager, CK-IMAGER

- 1024 x 1024 pixels with 0.2 x 0.2 mm² and 16 bits depth

- Temporal resolution: up to 25 fps

- Energy range: 40 kVp to 15 MVp

- A shielded cover: COVER-TRUE

- A dummy cover for CT-scanner: COVER-DUMMY

- A complete set of test objects and accessories: SLAB-FIDU, SLAB-CUBE, kV-TILT, kV-COPPER, kV-DISTO

-

The CK-PILOT software module for piloting the aquisition of MV images with the imager CK-IMAGER

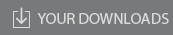

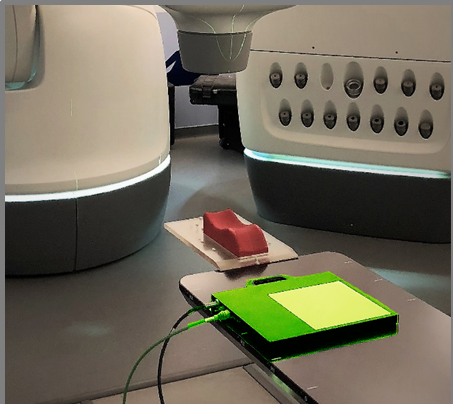

- The CK-COLLI software module which automatically analyses the images aquired with our CK-IMAGER in the context of QC of fields collimated by the cones and the iris

- Field size, circularity, symmetry and flatness tests

- Output Factors

- The CK-MLC software module automatically analyses the images acquired with our CK-IMAGER in the context of QC of the MLC

- « Garden fence » and « Picket fence » tests.

- Output Factors

- The CK-MU software module which automates the Monitor Unit constancy, repeatability and linearity with MV images acquired with the imager CK-IMAGER

- The CK-GEOM software module which automates without film the AQA test and another test completing it, as well as the imaging center test with the "isocrystal"

- The CK-CONVERT software module which converts to DICOM format images, from the two onboarded kV imagers of the CYBERKNIFE

- The EPID-KV+ software module automatically analyses the images aquired with the two onboarded kV imagers in the context of their QC

-

Geometric distortions, signal uniformity, noise, spatial resolution, contrast, ...

-

- The DOSE-R software module converts into DICOM format and automatically analyses depth dose curves, profiles and OCR curves measured with a water tank, a matrix or a profiler

Finally, by complementing QUALIMAGIQ with QUALINAX, our total and paperless management platform for all your QA and maintenance tasks, you will have a solution to automate 100% of your QCs, which will guide you step by step during their performing and which will provide you with a centralised storage of all your QCs measurements and data.

WHAT SOFTWARE CAN claim to DO AS MUCH AS QUALIMAGIQ and qualinax?!

CK-imager high-energy portable imager

A portable, electronic high performance imager for acquiring high-energy (MV) images of treatment beams used for the quality control of a CYBERKNIFE installation

Characteristics of the portable imager:

- Technology: flat panel

- Active surface: 1024 x 1024 pixels

- Pixel size: 0.2 mm

- Pixel depth (dynamic image): 16 bits

- Temporal resolution: up to 30 images per second

- Field of use: photon beam of a maximal surface of 200 x 200 mm² with an energy ranging from 20 keV to 15 MeV

Accessories supplied with the imager:

- AC/DC power supply

- AC power cord

- DC power cord: 7.6 m

- Ethernet cord for a computer (shielded RJ45) : 15 m

Accessories and test-objects supplied with the imager:

CK-COVER-TRUE

This cover protects the CK-IMAGER from shocks but it also protects its electronics from scattered radiations thanks to Tungsten alloy shielding.

This cover also makes it possible to install the CK-SLAB-FIBU and CK-SLAB-CUBE plates on the surface of the imager and it can be tilted by 35° with the CK-COVER-TILT accessory, which allows viewing on the same image the anterior beam and the lateral beam necessary for the “AQA” type test proposed ACCURAY.

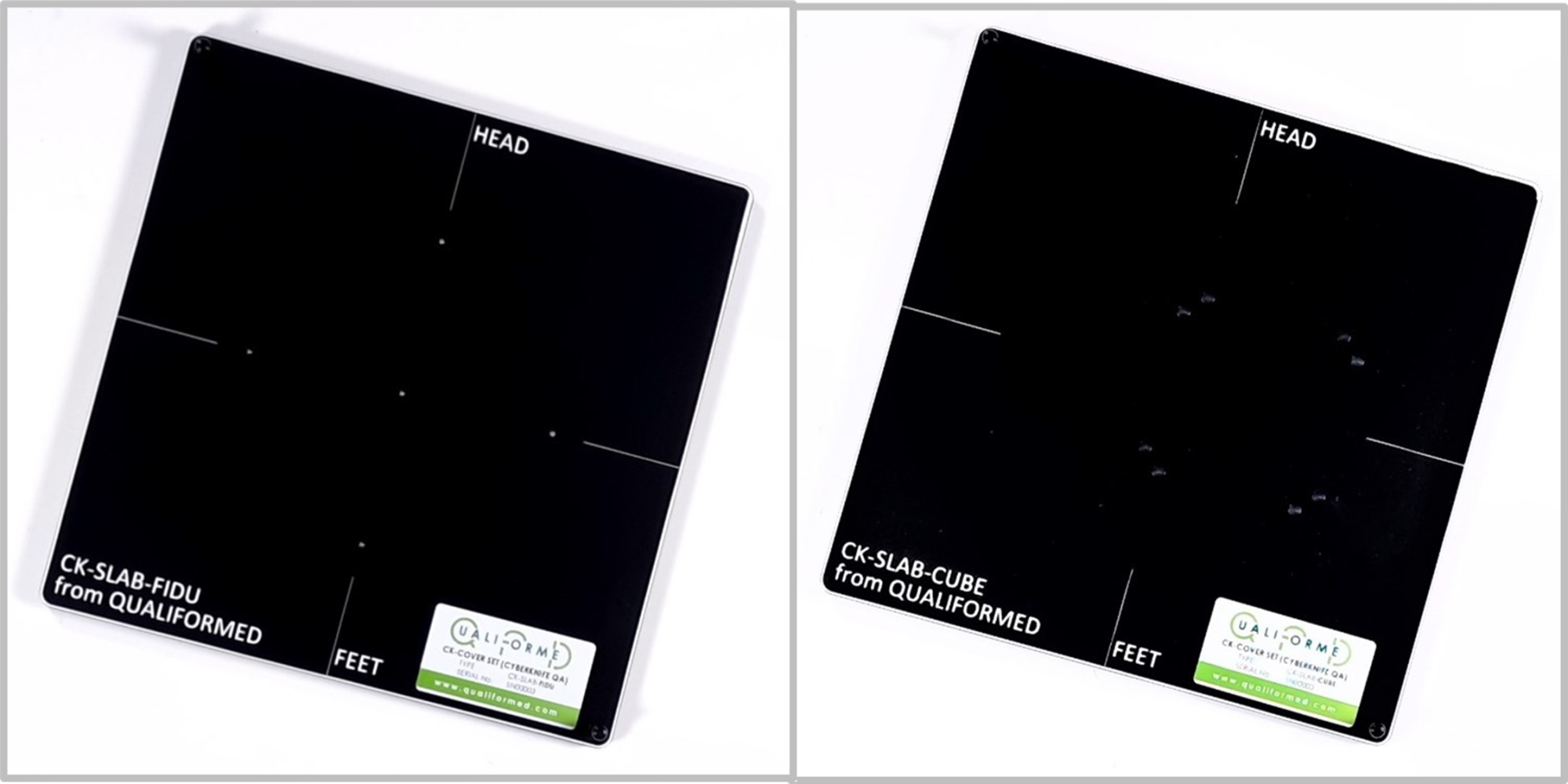

CK-SLAB-FIDU

This CK-SLAB-FIDU plate contains 5 fiducial markers allowing, on the one hand, to automate the positioning of the CYBERKNIFE machine in front of the CK-IMAGER, and on the other hand, to carry out a "Target > Fiducial markers" type test whose image is automatically analysed by the CK-GEOM module.

CK-SLAB-CUBE

This CK-SLAB-CUBE plate makes it possible to maintain on the CK-IMAGER surface, the BALL-CUBE phantom provided by ACCURAY to perform the “AQA” type test, this test being automatically analysed by the CK-GEOM module.

CK-COVER-DUMMY

This CK-COVER-DUMMY cover strictly reproduces the geometry of the CK-COVER-TRUE but it is entirely made of plastic materials which makes it possible to acquire CT-scanner images allowing to simulate on the ACCURAY TPS, the irradiation of the CK-IMAGER when it is locked in its CK-COVER-TRUE.

CK-COVER-TILT

This CK-COVER-TILT system tilts the CK-COVER-DUMMY and CK-COVER-TRUE covers (and therefore the CK-IMAGER imager), which makes it possible to visualise on the same image, the anterior beam and the lateral beam used to carry out the “AQA” type test.

CK-COVER-TRUE

CK-SLAB-FIDU CK-SLAB-CUBE

CK-COVER-DUMMY CK-COVER-TILT

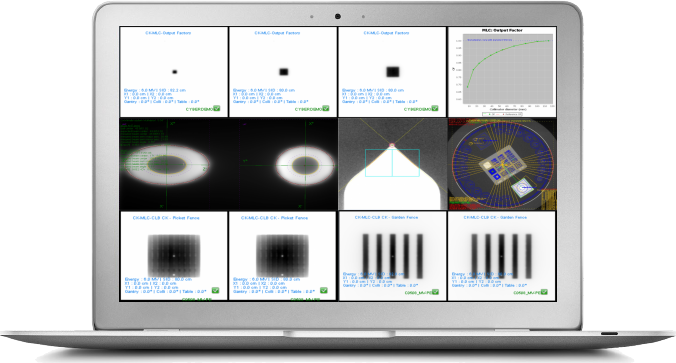

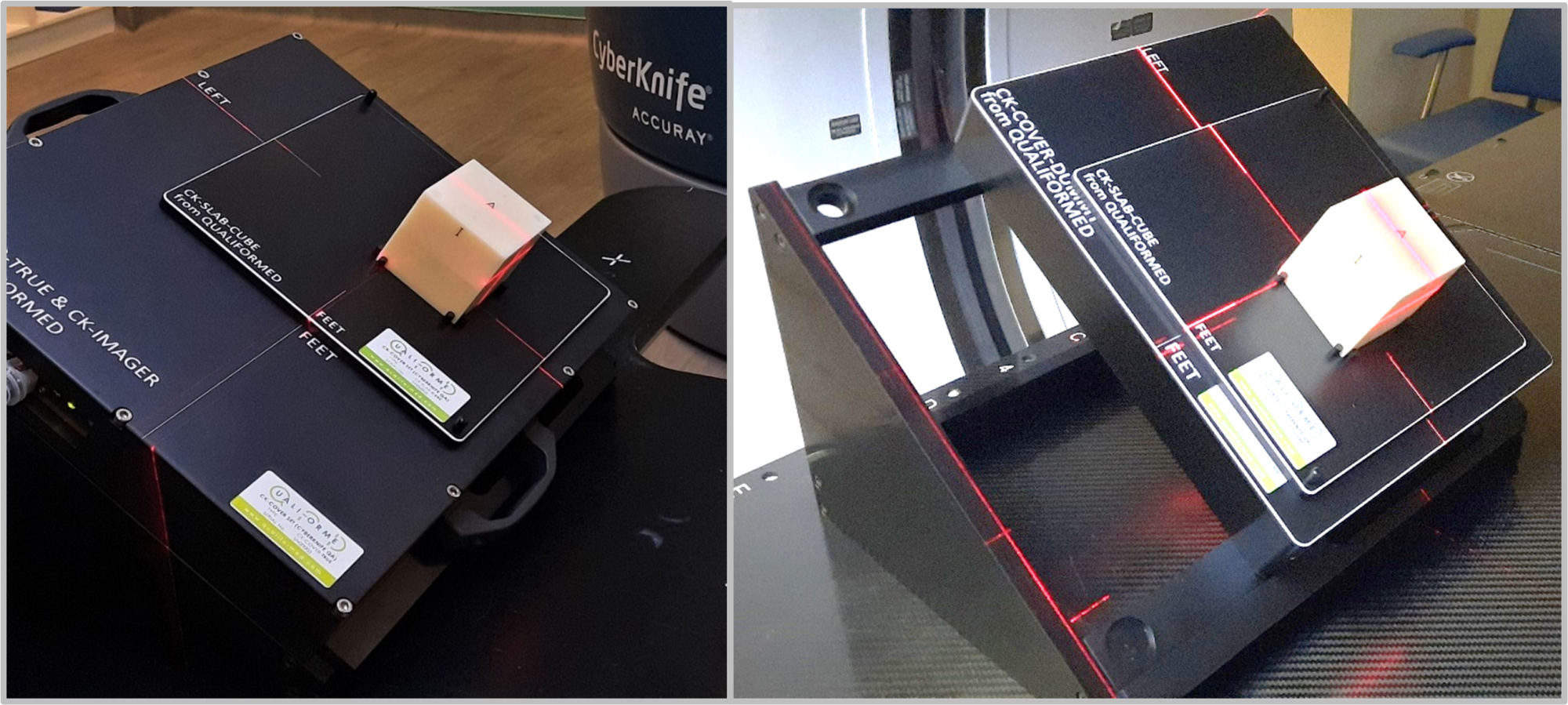

Set up examples of these ck-imager accessories with the accurayTM ball-cube Phantom:

Figure 1. Figure 2.

Figure 1:

The 3 accessories CK-COVER-TILT, CK-COVER-TRUE and CK-SLAB-CUBE associated with the BALL-CUBE phantom: This set is in place to visualise in a single image the 2 beams necessary for the test of the “AQA” type.

Figure 2:

Same configuration as in figure 1, but this time at the CT-scanner and with the CK-COVER-DUMMY accessory instead of the CK-COVER-TRUE, to simulate on the ACCURAYTM TPS the geometric conditions of irradiation of the “AQA” type test carried out with our CK-IMAGER.

Resources

- QUALIMAGIQ-Brochureemail requiredPDF Format

- QUALINAX-Brochureemail requiredPDF Format

- QUALIMAGIQ-CK-Brochureemail requiredPDF Format

You need a user manual? Please contact us.

Your brochure request has been added to your Download Cart.

At the end of your visit:

- Please click the "YOUR DOWNLOADS" button at the top right,

- Complete the form and SEND it.

You will get the documents shortly by email.