Automates and Organises Quality Assurance in Radiation Therapy and Medical Imaging

MOD MLCstat

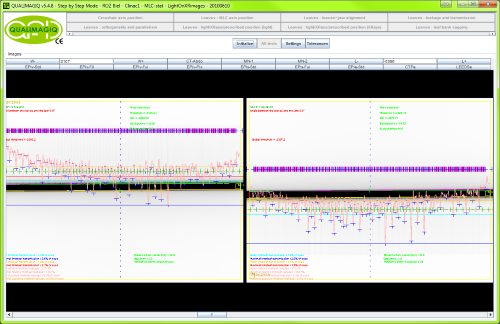

QUALIMAGIQ module for a complete and fully automatic QA of the multi-leaf collimator (MLC) used in a static mode

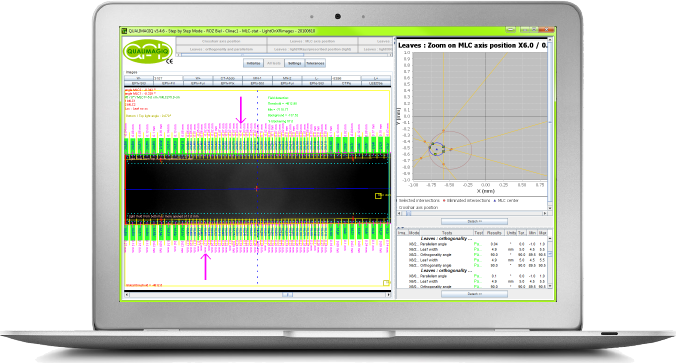

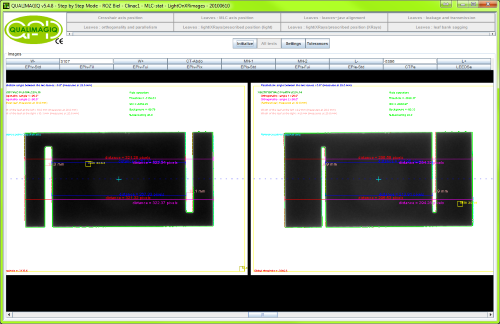

Connected to the QUALIMAGIQ platform, it takes the MLC-stat module only 2 mouse clicks to analyse the DICOM images acquired with the treatment machine’s high energy portal imager during mechanical and dosimetric quality control of a multi-leaf collimator (MLC) used in static mode

BY FAR The BEST SOLUTION FOR MLC QA!

The automated analyses include those associated with the controls proposed by the SFPM (French Society of Medical Physicists, 2003 Report N°20) and by the French Agency AFSSAPS (JORF dated 9/9/2007):

- The rotation axis of the reticule and the quality of its rotation, tests which can be performed at varying distances from the source.

- The rotation axis of the MLC and the quality of its rotation.

- Centring of the reticule in relation to the centring of the MLC.

- Accuracy of the MLC rotation angles.

- Parallelism of the leaves in relation to the simple jaws which are parallel to them;

- Orthogonality and symmetry of the leaves in relation to the simple jaws which are perpendicular to them;

- Concordance of the prescribed MLC fields and of the light MLC fields relative to the irradiated MLC fields;

- Accuracy of MLC leaf positioning, different tested fields in regard to both the irradiated fields as well as the light fields;

- Maximal and mean transmissions of the leaves (intra-leaf leakage);

- Maximal and mean transmissions between two adjacent leaves (inter-leaf leakage;

- Sagging of the leaf banks due to gantry rotation.

- Maximal and mean transmissions between two opposite leaves mechanically abutted one against the other (work in progress);

Important note: most of the tests use automatic detection of beam limits defined by an iso-blackening whose level can be parameterized by the user. Prior to this detection the signal is over-sampled so it is no longer contingent upon the sensor’s resolution. These 2 specificities render QUALIMAGIQ analyses conclusive, without false positive or false negative results.

Specifications

Less than 30 minutes is all the time you need to perform the entire control: installation of the test objects, image acquisition and analysis, editing of 6 different PDF analysis reports and a trend curve for each tested parameter.

This module enables you in particular to optimally fulfil requirements of the French National Agency for the Safety of Medicines (ANSM) decision dated 28/02/23 regulating the procedures for quality control of external radiation therapy and radiosurgery devices: points 3C.1.1, 3C.1.2, 4A.1.3 and S1.1.2 of the annex.

Associated test objects: OTP-FIELD28 (or OTP-FIELD-18 with an HD type of MLC), OTP-BALL and OTP-ALIGN from QUALIFORMED.

resources

You need a user manual? please contact us.

FAQ

IN THE BEST CONFIGURATION, The resolution of the portal imager is 0.25 mm at the isocenter. with that condition how the module is capable to give the leaf position with a beTter resolution than 0.1 mm?

The software interpolates pixel intensity profiles with a polynomial regression.

The radiation leaf position normally corresponds to the 50% of the dose at 10 cm depth in the water. How the software is capable to find this level of dose in the water with a portal imager?

The superuser can adjust in the software the threshold signal corresponding to this level of dose. It's very important to evaluate this threshold for each new portal imager. By cons, for a same portal imager, the threshold value is stable in the time.

For the leaf position tests, how the software reacts to "deAd" pixels?

The position of each leaf is evaluated with a minimum of 6 pixels intensity profiles. On each of these profiles associated to a leaf, the leaf position is found. And the software applies a median filter on these leaf positions in order to reject aberrant positions. With the rest of leaf positions of one leaf, the software does a linear regression to find the radiation edge of the leaf.

The sensitive size of AN ELEKTA portal imager is 260 x 260 mm² at the isocenter. In that condition, how the module is capable to test all MLC leaves?

The module can analyse composite images, i.e., 2 or 4 images acquired with the same MLC configuration. In between the portal imager is respectively shifted in longitudinal or longitudinal and transversal directions to produce these 2 or 4 images. The module assembles these composite images with a common reference point from the source (a metallic ball installed at the exit of the MLC) and common direction (the leaf alignment).

Your brochure request has been added to your Download Cart.

At the end of your visit:

- Please click the "YOUR DOWNLOADS" button at the top right,

- Complete the form and SEND it.

You will get the documents shortly by email.