Automates and Organises Quality Assurance in Radiation Therapy and Medical Imaging

Connected to the Qualinax platform, it guides you step-by-step through all Quality Controls (QC) of your electron accelerators for medical use, indicating the appropriate operating procedures to apply, and illustrating them with multimedia demonstrations (texts, photos, audio messages and videos). This component allows you to confidently delegate your QC.

CMP-QC: « DECLARATIONS » FUNCTIONS

In this section the system administrator declares:

- The inventory of the treatment machines to be controlled, using an interface composed of the following five tabs:

-

« Identification » of the installation,

-

« Mechanical specifications » of the installation, using very visual interfaces to specify all the mechanical possibilities for each treatment machine,

-

« Dosimetric specifications » of the installation, specifying all dosimetric possibilities of the installation: particles, energies, wedge filters, electron applicators, monitor units…

-

« Safety systems » of the installation, again with a very visual interface enabling the user to rapidly parameterise the lay-out of the treatment room and the control room by choosing those safety systems to be controlled from the list of typical devices provided and positioning them in the 2 interactive room blueprints. Photos of the safety systems may be added to the declarations. The digital blueprint will be used when controlling performances of safety systems.

-

« Interlocks »: in this tab the user declares the “interlocks” he would like to test.

-

- The team members responsible for Quality Controls (QC) of the treatment machines: last names, first names, e-mail addresses, time to be allotted to QCs, staff level, certifications, rights on software use and on QC performance workflows.

- Available QC equipment: phantoms, water tank scanning systems, matrix detectors…, including the management of their calibration and multimedia documentation describing their use.

- The control points, which correspond to elementary tests, whose operating modes used to perform them are presented through intuitive interfaces and multimedia input (photos, videos, audio messages, texts). These control points also specify the length of time the test requires as well as the level of the person qualified to perform the test.

- The quality controls, which consist of a number of control points performed in an order pre-determined by the system’s super-user. Naturally, several quality controls may coexist for the same installation, each for instance differentiated by its scheduling frequency and contents.

CMP-QC: « PERFORM QC » FUNCTION

Here the standard user is provided assistance throughout the entire phase of Quality Control performance:

- Each control point contained in the quality control is presented step by step in the order determined by the system’s super-user. The interface associated with the control point underway presents the operating mode through multimedia displays: photos, videos, audio messages and texts.

- Upon completion of each control point, QUALINAX retrieves all acquired measurements ("portal" images, dose measurements made with the water tank scanning system, forms, keyboard data entries, MS-EXCEL® spreadsheet cells…) and saves them in the QUALINAX database.

- A flowchart depicting the various steps in the performance of the QC provides continual feedback on the user’s progress on the quality control and the estimated time at which control operations will be completed.

CMP-QC: « ANALYSE QC » FUNCTION

This feature of the program automatically enables the following operations:

-

Formatting the “measurements” acquired in the various stages of quality control1: "portal" images as well as relative dose measurements issuing from the water tank scanning system, to be analysed by various QUALIMAGIQ2 modules, digital forms on control of safety systems and "interlocks" (MOD-SAFE module), control forms of MU calibration (MOD-DOSE-A module), and “in-house” QC forms (MOD-FREE module),

-

Transferring the formatted measurements to the different automatic analysis modules of the QUALIMAGIQ2 software platform,

-

Retrieving and storing the various results of the analyses automatically generated by QUALIMAGIQ2: QC measurement analysis results in XML format and the corresponding analysis reports in PDF format.

CMP-QC: « VIEW QC » FUNCTION

An intuitive interface to conveniently consult:

- The analysis reports created in PDF format, either individually for each module, or for the entire QC,

- The temporal evolution of any monitored parameter for a selected installation.

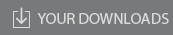

Interface for declaring the treatment machine’s colimator characteristics

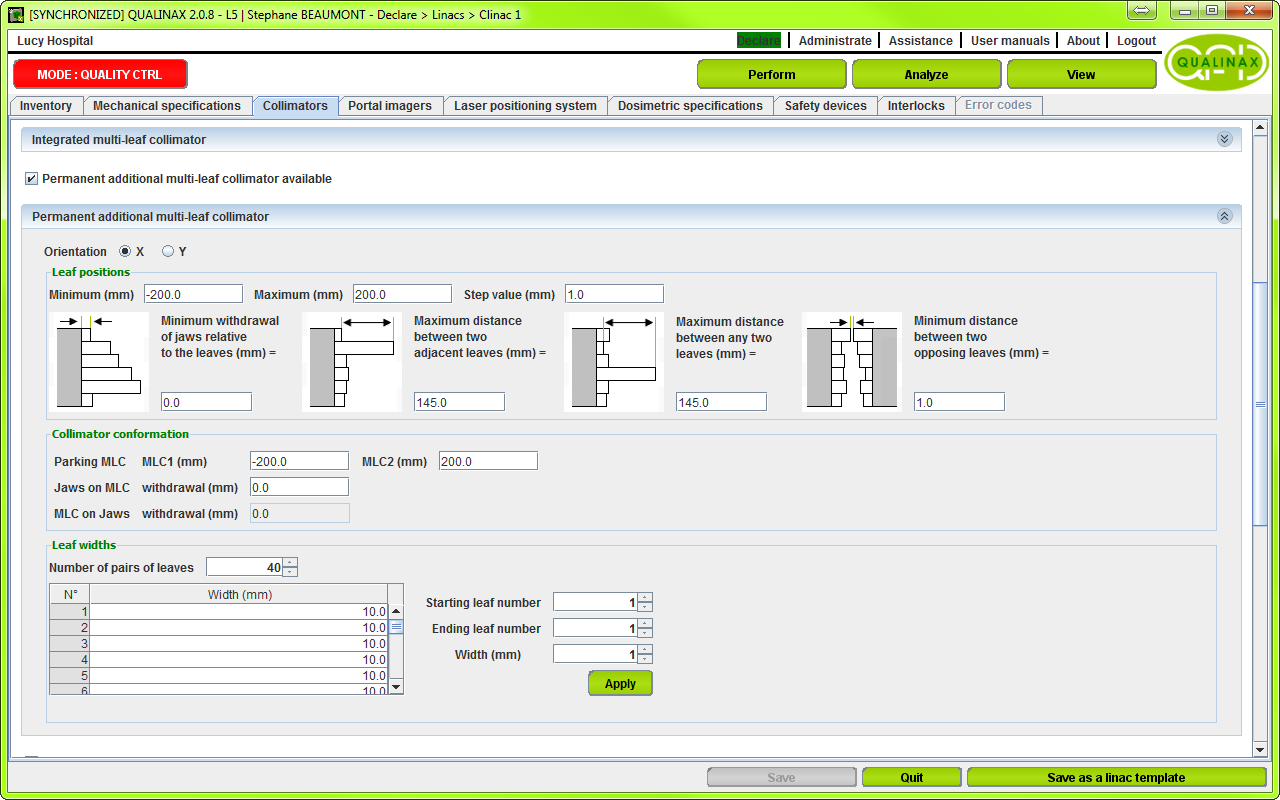

Interface for declaring the treatment machine’s safety systems

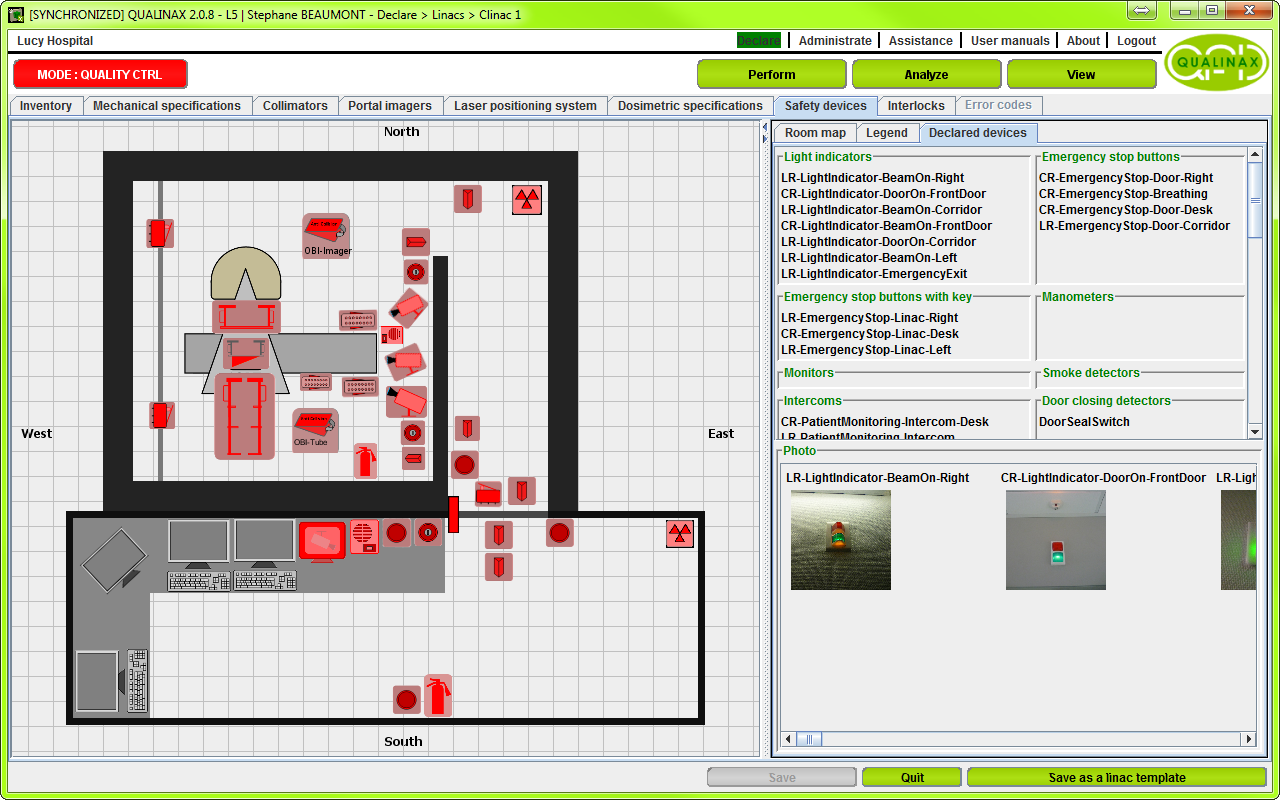

Register of the inventoried QC tools

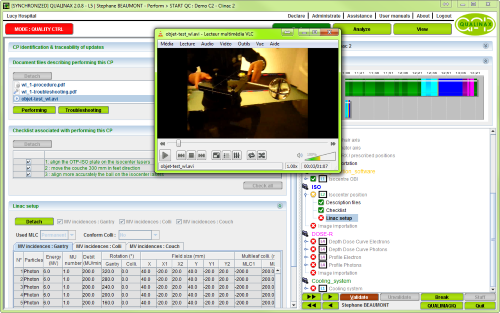

QC performance assistance screenshot at the step performing the Winston & Lutz test used to determine the size and the position of the radiation isocentres:

- On the left side, the operating mode illustrated with texts and videos,

- In the middle, a video clip demonstrating how to install the phantom,

- On the right side, a flowchart which tracks the progress of the various QC steps,

- And a timeline listing both the projected and actual durations for performance of each QC step.

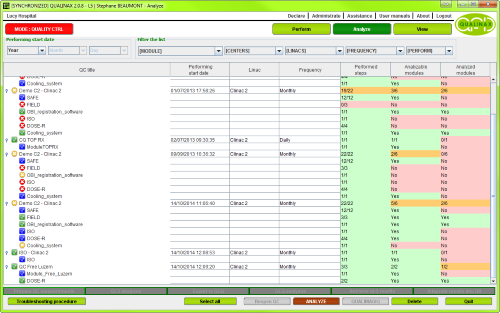

Interface for preparing automatic analyses of performed QCs

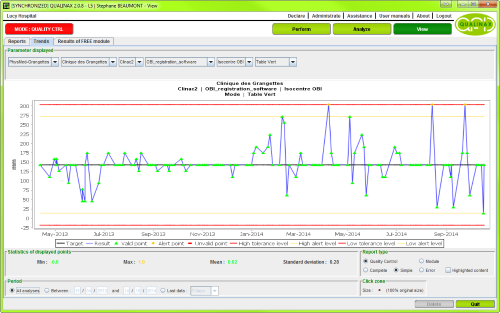

Consultation screen displaying the temporal evolution of a monitored parameter.

This interface also enables you to display the quality control report you wish to consult simply by clicking on the point along the curve which corresponds to the date of the particular control.

(1): This functionality depends on the QUALINAX modules for performance and analysis and the QUALIMAGIQ analysis modules acquired.

(2): The QUALIMAGIQ solution is not included in the basic QUALINAX offer. Furthermore QUALINAX, together with its MOD-FREE module, can also operate with QC measurement analysis software other than QUALIMAGIQ.

Resources

You need a user manual? please contact us.

Your brochure request has been added to your Download Cart.

At the end of your visit:

- Please click the "YOUR DOWNLOADS" button at the top right,

- Complete the form and SEND it.

You will get the documents shortly by email.