Automates and Organises Quality Assurance in Radiation Therapy and Medical Imaging

QUAlinaX

All your QA and maintenance tasks of radiation therapy and medical imaging devices, all your data centralised on a single paper-free platform

The most complete and detailed solution on the market

Perfect to efficiently assist you in all stages of your quality controls (qC) and maintenance tasks

- Simplifies, organises, traces and closely follows tasks

- Centralises in a single database all information related to these tasks

- Features an intuitive workflow based on user-friendly interfaces

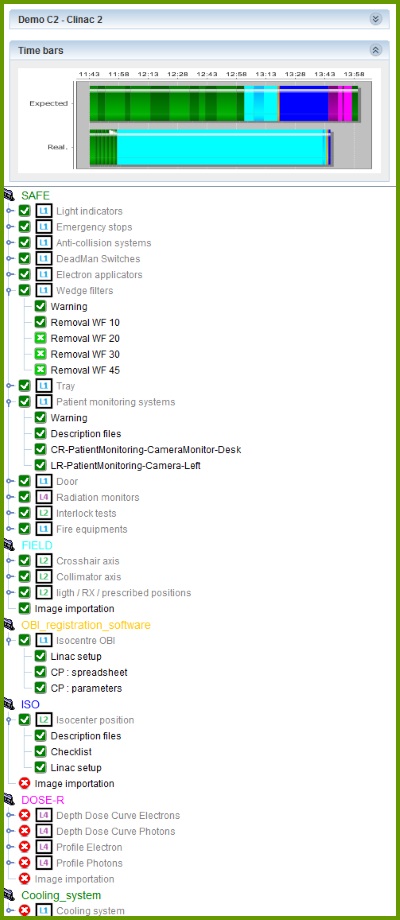

- Optimised to work together with the QUALIMAGIQ1 platform for automatic analysis of QC measurements

- Highly parameterisable to adapt to your specific demands

- Modular so you can purchase only those elements you need

A powerful tool which includes:

- Computerised scheduling of QC and maintenance tasks

- Assistance performing these tasks

- Modules for automatic analysis of QC measurements

- A detailed overview of the tasks performed, in particularly in regards to the planned schedule

- Comprehensive traceability of these tasks

- Management of the spare parts inventory, QC equipment and of the staff in charge of these tasks

- A computerised journal of events occurring on your LINACS

Efficiently manage the QC & maintenance2 of your linacs:

- Through a paperless, centralised and complete solution, providing multiple tools for scheduling and traceability

- Accessible to each member of your team, in accordance with his level

- Offering clear and customisable interfaces

- Enabling you to confidently delegate the performance of these tasks

- And to analyse all QC measurements in just one mouse click

optimal and paperless organisation to assist you in:

- Scheduling, performing, following and documenting all of your QC and maintenance tasks2

- Declaring breakdowns and corrective maintenance, obtaining diagnostic aid2

- Managing spare parts inventory2, your QC equipment and your human resources

- Collecting, analysing, viewing the QC measurements (PDF reports and trend curves) as well as maintenance data

A tool which is comprehensive, powerful and manufacturer-independent which greatly adapts to your specific needs

-

You remain in charge of choosing which QCs you wish to implement by parameterising their performance workflow, analyses and associated reports

-

You decide the level of documentation of your QCs and the degree to which you wish to automate their analyses

-

You confidently delegate the QC and maintenance tasks2 of your LINACS given the rigorous and well-suited management of the performance levels of these tasks and of the user levels provided by the software solution

3 optional modules which assist you in performing very specific QCs

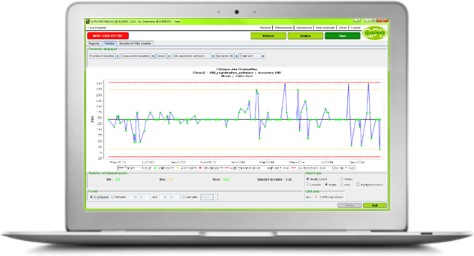

- MOD-SAFE: QC of the safety devices and interlocks

- MOD-DOSE-A: MU calibration QCs

- MOD-FREE: your "in-house" QCs are also covered as well as QCs which are analysed by software other than QUALIMAGIQ1

3 optional components so you decide what you wish the software to manage

- CMP-SCHED to automatically manage the scheduling of your QC & maintenance tasks

- CMP-EVENT to automatically manage, edit and print computerised tracking logs of the events occurring on the installations which you control

- CMP-MAINT2 to manage in QUALINAX the maintenance tasks performed on these installations

What software can deliver as much as QUALINAX does in its field?!

1: QUALINAX can also operate with QC measurement analysis software other than QUALIMAGIQ

2: The functionalities specifically dedicated to maintenance tasks are currently in the final stage of development. You may already document and follow maintenance tasks now with the events journal (CMP-EVENT)

Why choose qualinax ?

QUALINAX is the first and the most complete software solution available on the market to assist you in the performance, planning and traceability of all Quality Control (QC) and maintenance tasks carried out on external radiation therapy treatment machines (LINACs).

This modular solution is constructed around the QUALINAX platform, a database and various software components (CMP-) and modules (MOD-), installed to address specific Client needs, mainly the following:

- Whether or not you wish QUALINAX to manage maintenance (CMP-MAINT2 component),

- The degree to which you would like to automate analysis of QC measurements (QUALINAX analysis modules MOD-DOSE-A, MOD-SAFE and MOD-FREE, together with QUALIMAGIQ1 analysis modules),

- The desired degree of assisted scheduling of QCs and maintenance (CMP-SCHED and CMP-EVENT components),

- And finally, the number of medical devices to be managed by QUALINAX.

QUALINAX provides a set of software tools which mainly enable the following actions:

- To schedule the Quality Control (QC) and maintenance2 tasks and to view through these schedules those tasks which have been performed, those which should have been performed and last, those which are scheduled to be performed in the future,

- To describe step by step, in particular by documenting them, all QC and maintenance2 tasks, using customizable interfaces which integrate multimedia « documentary files » (PDF files, videos, audio messages, photos…) describing each step of these tasks, the list of required materials (inventoried or generic), warning messages, checklists, the required user level for performance, the length of performance time…,

- To perform such tasks with the permanent assistance of these customisable interfaces which guide the "performer",

- To collect and store all QC measurements and maintenance2 data during their performance,

- To automatically analyse these QC measurements with or without the aid of the complementary QUALIMAGIQ1 platform,

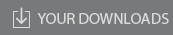

- To consult the QC measurement analysis results (PDF reports and trend curves) and the maintenance2 data,

- To view a summarised set of all performed QC and maintenance2 tasks, this view being included in an events journal; this journal can be entirely parameterised and can replace the tracking log of each controlled installation,

- To declare breakdowns and corrective maintenance2 servicing requests,

- To obtain diagnostic aid to repair the breakdowns2,

- To manage spare parts inventory and to automatically calculate availability rates of installations,

- To manage QC and maintenance tools (storage location, calibration validity dates…),

- To manage the human resources required to perform the QC and maintenance2 tasks (rights required to carry out the performance workflows, certification validity, schedules…).

The main QUALINAX functions are accessible through interfaces which contain mostly buttons and tabs which guide and accompany you throughout the entire course of your work.

THE BASIC QUALINAX PACKAGE INCLUDES THE FOLLOWING:

- A relational database and a file database enabling storage of all information required for the planning, performance, analysis and viewing of QCs and maintenance2 of a park of treatment machines:

- storage of declarations of users, installations, spare parts inventory2, QC and maintenance tools2, Control Points (CPs), QCs (sets of CPs), maintenance tasks2,

- storage of QC measurements and of their analysis results (XML files and PDF reports), storage of the descriptions of performed maintenance tasks2 …,

- The QUALINAX software platform, through which you may interface and exchange information with its two databases regarding the performance of quality control (QC) and maintenance tasks2,

- The CMP-QC software component for assistance in carrying out all “traditional” quality controls of treatment machines excepting those which are specifically devoted to safety systems and to calibration of “Monitor Units” requiring, respectively, the MOD-SAFE and MOD-DOSE-A modules. The CMP-QC component receives, stores and formats the quality control measurements, which it sends to the QUALIMAGIQ1 software platform for analysis. It then retrieves and stores these analysis results.

QUALINAX OFFERS THE FOLLOWING 3 OPTIONAL SOFTWARE MODULES (MOD-) AND 3 OPTIONAL SOFTWARE COMPONENTS (CMP-):

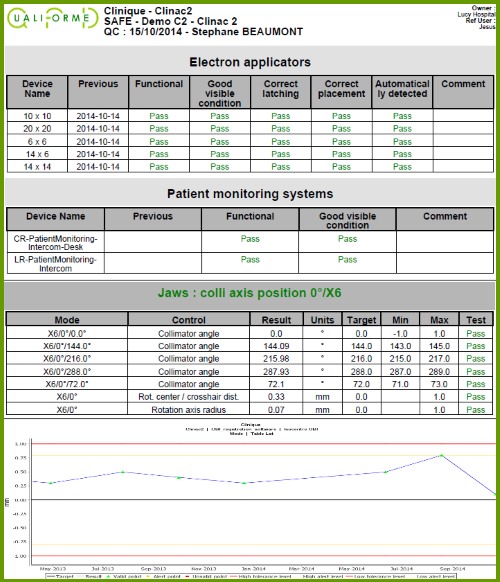

- MOD-SAFE: this module assists in carrying out quality controls (QC) of safety devices and interlocks, edits and automatically analyses the digital forms containing the control results of this type of QC.

- MOD-FREE: this module assists in carrying out “in-house” quality controls, creates, edits and automatically analyses for this type of QC the digital forms containing control results and/or extracts such results from an MS-EXCEL® spreadsheet, or else retrieves PDF analysis reports originating from a third party automatic QC analysis solution.

- MOD-DOSE-A: this module assists in carrying out controls of “Monitor Unit” (MU) calibration, edits and automatically analyses the digital forms containing the control results of this type of QC.

- CMP-SCHED: this component automatically manages the scheduling of QC and maintenance tasks2.

- CMP-EVENT: this component enables you to automatically manage, edit and print the digital registries of events occurring on the managed installations, events which are either automatically generated by your work in QUALINAX or manually entered in the dedicated interfaces by the various operators.

- CMP-MAINT2: this component enables you to interface and exchange information with the relational database included in QUALINAX in regards to the performance of maintenance tasks. This component also provides diagnostic assistance available during corrective maintenance as well as inventory management of spare parts.

QUALINAX has been optimised to work in conjunction with the QUALIMAGIQ3 platform and its many software modules which automatically analyse measurements derived from quality controls of external radiation therapy and medical imaging installations.

QUALINAX downloads the QC measurements to QUALIMAGIQ3 for analysis. The analysis results (XML files) and corresponding PDF reports are then sent back to QUALINAX.

QUALINAX ENSURES THE TRACEABILITY OF ALL OF YOUR quality CONTROLS BOTH SIMPLY AND ACCURATELY

Once again, it’s quite simple, no need to manipulate files: just select the installation you wish to view and the type of parameter whose evolution over time you would like to study. The system provides the evolution curve for the selected parameter.

Clicking on any given point of the curve provides direct access to the 6 PDF reports associated with the measurement, generated either directly by QUALINAX or by QUALIMAGIQ1:

- A simplified report listing all tested parameters, their measurements, associated target values and tolerances as well as their status (Pass / Warn / Fail),

- An error report limited to those parameters warned or failed from the simplified report (at alert level or outside of tolerance),

- A full report composed of the simplified report together with the images, on which their associated measurements are superimposed.

The above 3 types of PDF analysis reports are doubled by creation of 3 more PDF reports containing only those parameters which have been highlighted

QUALINAX operates in Client/Server mode

The QUALINAX platform can be deployed in Client/Server mode in the following optimal manner:

- The QUALINAX database and the QUALINAX and QUALIMAGIQ1 applications are installed on a virtualised served hosted on a physical server.

- Clients connect to QUALINAX and QUALIMAGIQ1 with terminals which are thin clients, and which are also virtualised and hosted on the same physical server.

In this configuration:

- Client desktop / Server exchanges are minimal, as only the keyboard and refresh commands are transmitted over the physical network.

- QUALINAX and QUALIMAGIQ1 may be used simultaneously on several different Client desktops, with the two applications managing any possible conflicts by temporarily limiting designated actions by certain users when other users perform related tasks or when the administrator is configuring the system.

3: The QUALIMAGIQ solution is not included in the basic QUALINAX offer. Furthermore QUALINAX, together with its MOD-FREE module, can also operate with QC measurement analysis software other than QUALIMAGIQ.

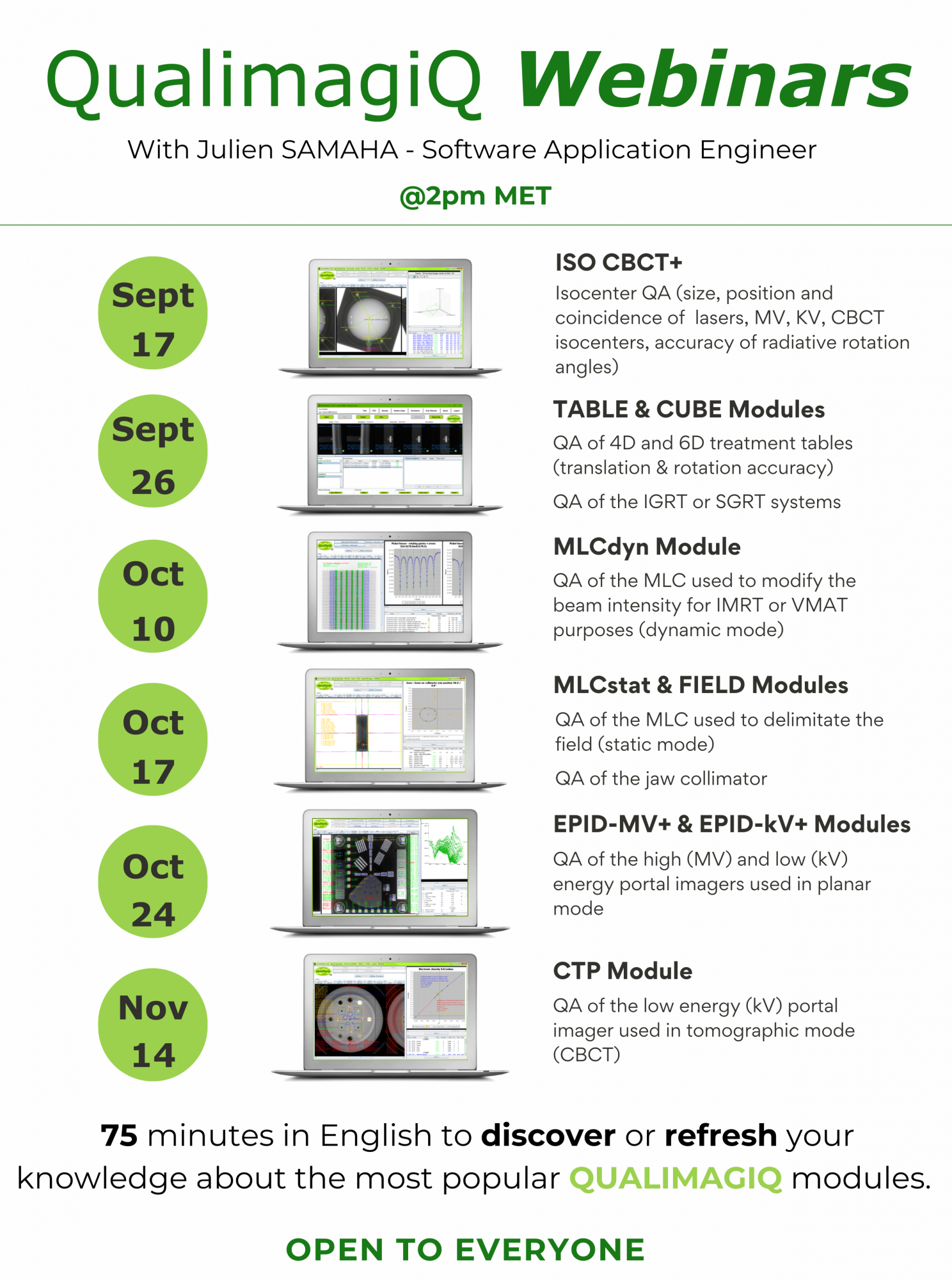

To register, please send your information at:

sabrina.gauducheau 'at' qualiformed.com

Specify your name, function, name of center, phone number, email and the choice of webinar(s) you would like to participate in.

Location: The comfort of your own office or home

Hosted by: Julien Samah & Karsten Salomon

Event Format:Online- You'll recieve the link via email after resgistration for the selected session(s).

Your brochure request has been added to your Download Cart.

At the end of your visit:

- Please click the "YOUR DOWNLOADS" button at the top right,

- Complete the form and SEND it.

You will get the documents shortly by email.